Beam Profile Measurement System measures the light emission pattern of a light source. The light source can be LED, optical fiber output, or waveguide output. It is very important to know the beam profile because Photonics deals with light. For example, a lens is prepared to focus the light of a LED. The lens should have proper size and curvature to focus the light efficiently. The beam shape of the LED should be known to determine the size and curvature of the lens. In addition, you may need to know the beam divergence.

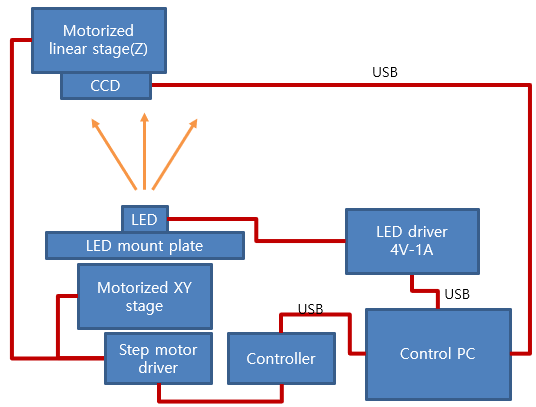

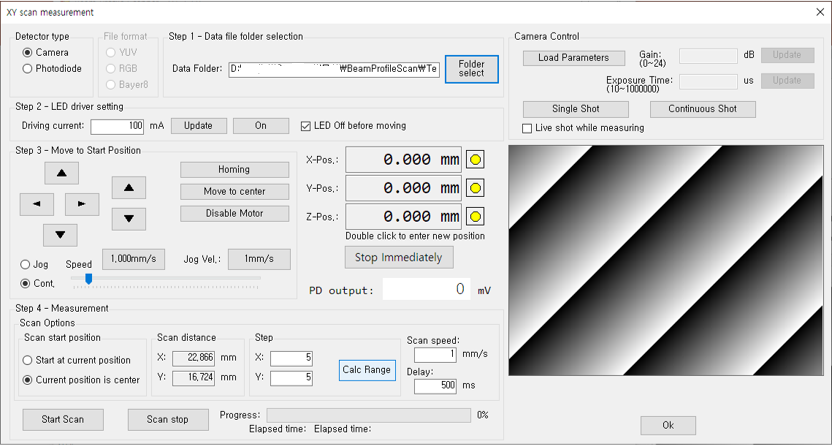

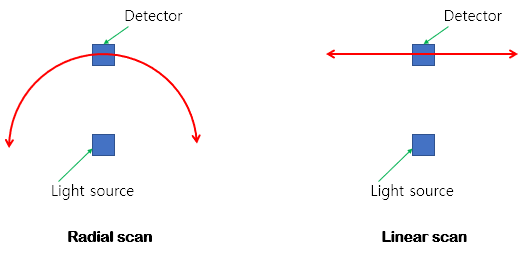

A detector such as a photodiodoe, a CCD or a spectrometer is attached to a moving stage. A control GUI program controls the moving stage. The moving stage moves around the light source. It moves in a radial or linear direction.

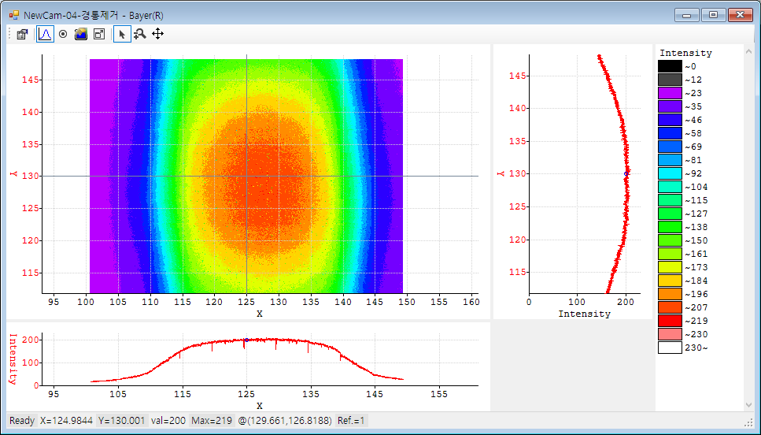

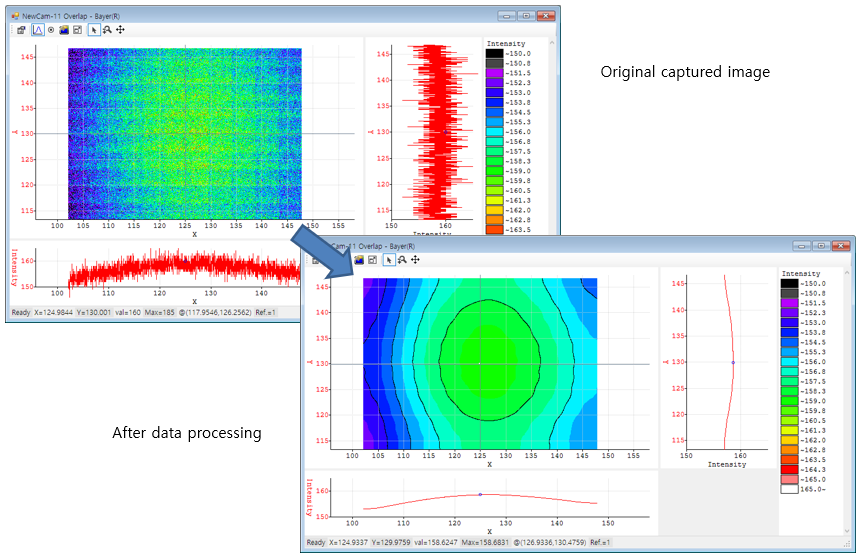

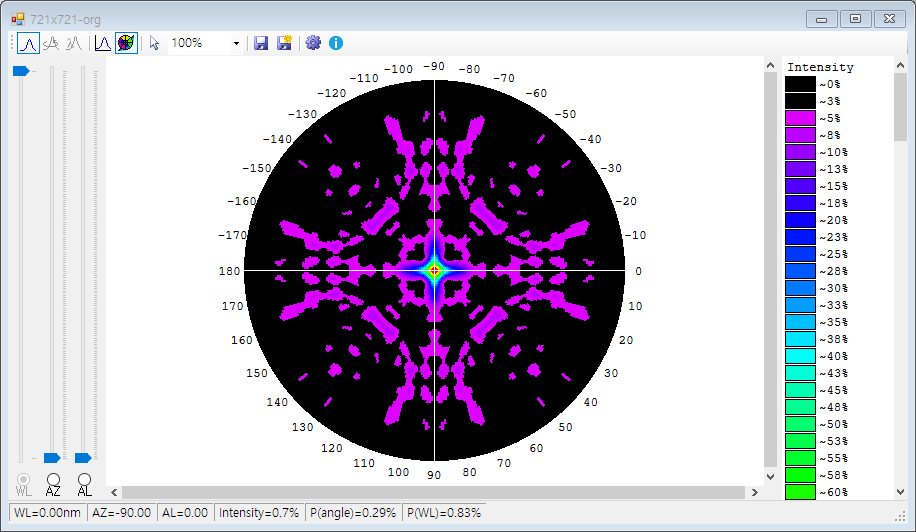

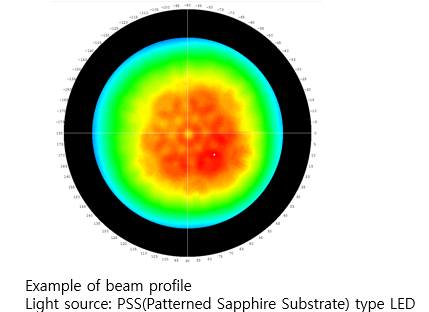

The GUI measures the detector output while it moves the detector. The measured detector output data are analyzed according to the detector position to calculate the beam profile. The GUI displays the beam profile graphically. The following picture shows the example of LED beam profile.

The detector moves in radial direction. Red color denotes higher intensity and blue color denotes lower intensity.

The beam profile measurement system can be configured according the customer's needs. The detector can move in radial direction or linear direction. The detector can be a photodiode or CCD sensor. The light source stage is fully customizable.

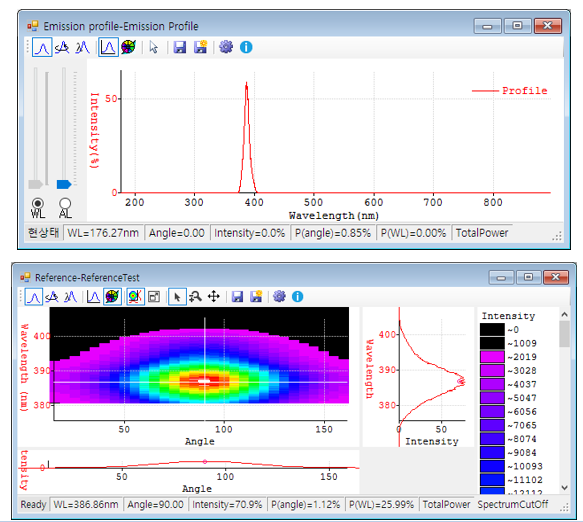

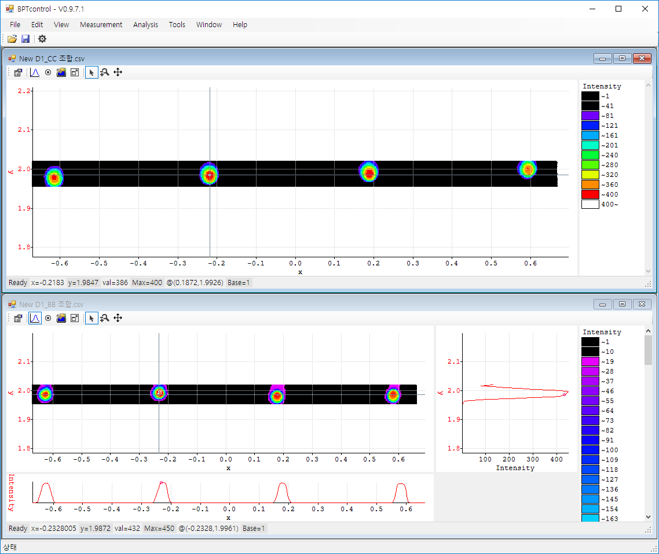

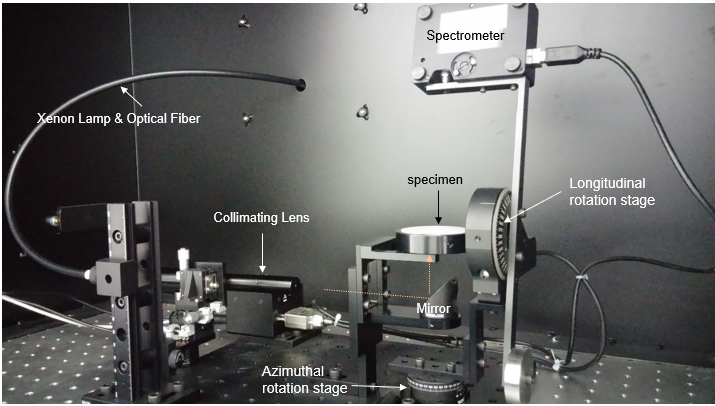

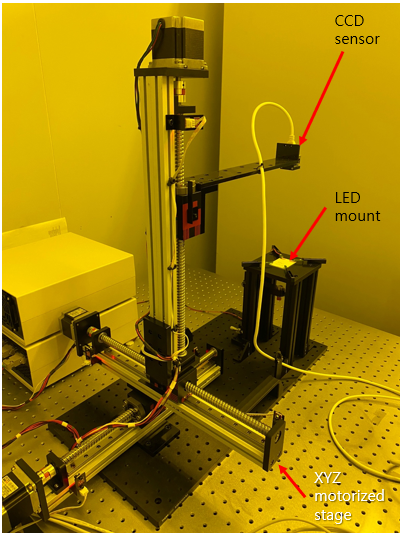

The above photo shows example of beam profile measurement system. It has radial scan stages and the detector is a spectrometer. The light source is Xenon lamp. The follwing beam profile measurement system uses linear moving stages for scanning. The detector is CCD sensor and the light source is LED.

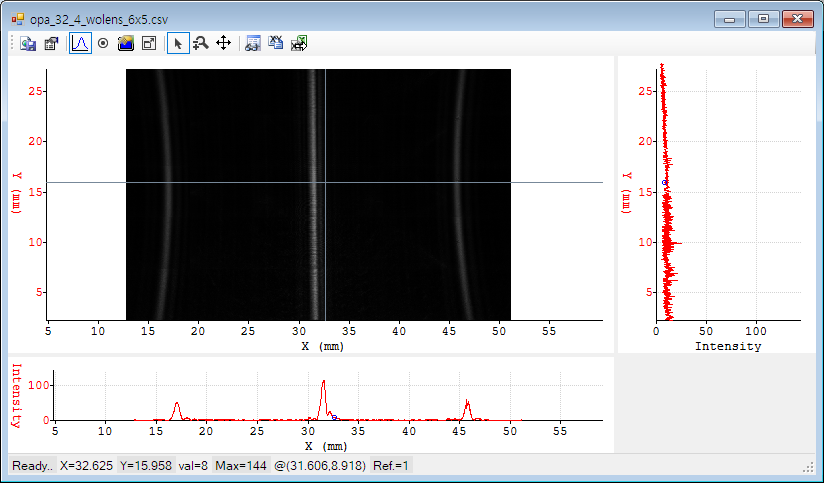

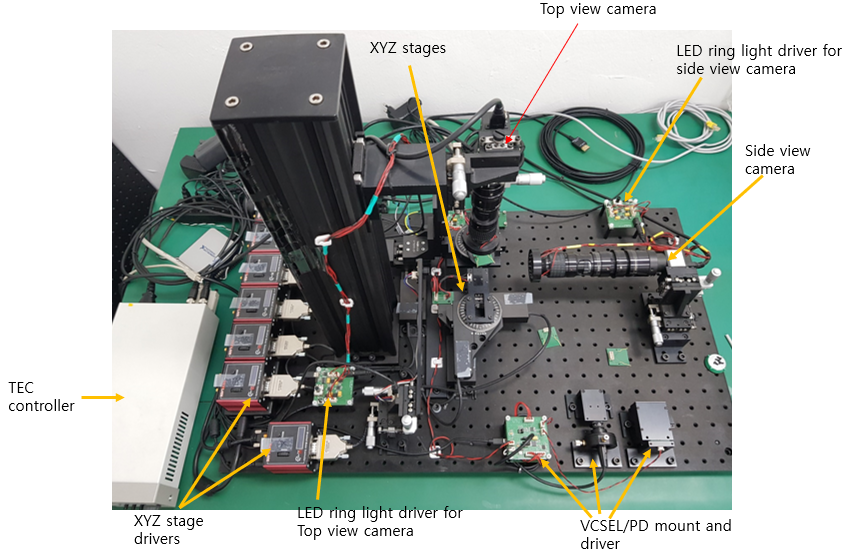

Several options can be added as well. The following system evaluates the lens array. It has two cameras to observe the lens array. TEC controller controls the thermoelectric cooler that is attached the sample holder to maintain the temperature of the light source. 6 motorized linear stages and 2 motorized rotation stages are used to measure the characteristics of the lens array precisely.

All beam measurement systems are customized. You can choose the type and vendor of the moving stages. The detector type can be selected. If you are not sure which moving stages and detectors are suitable for you, just leave it to us, We will think and decide for you.